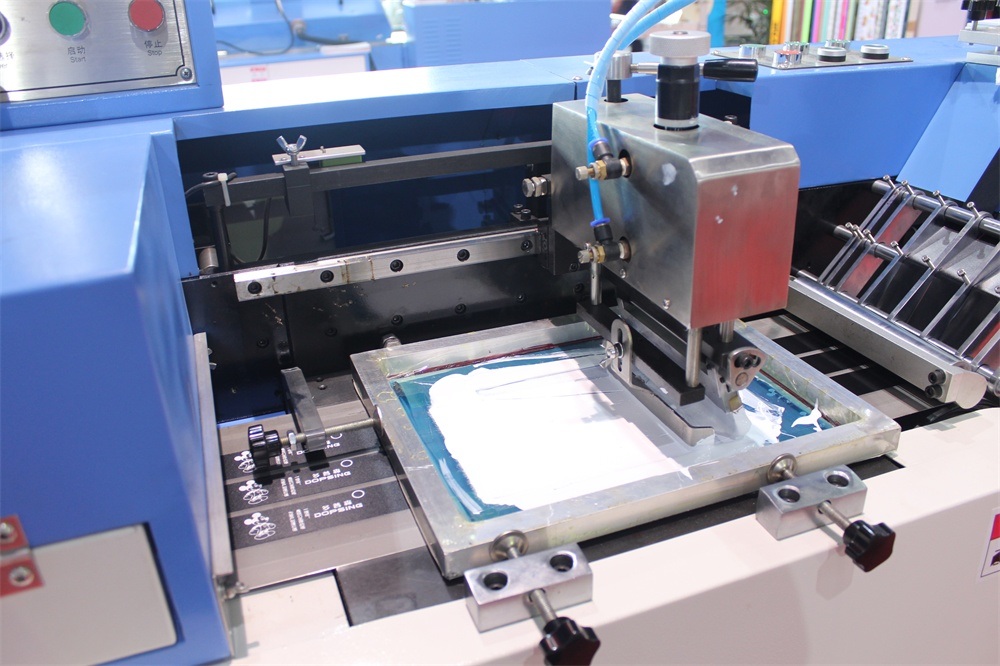

Factory Price Nylon Bra Tapes Starching And Finishing Machine - Double Sides Cotton Tapes Automatic Screen Printing Machine – Kin Wah Detail:

Basic Info

Product Description

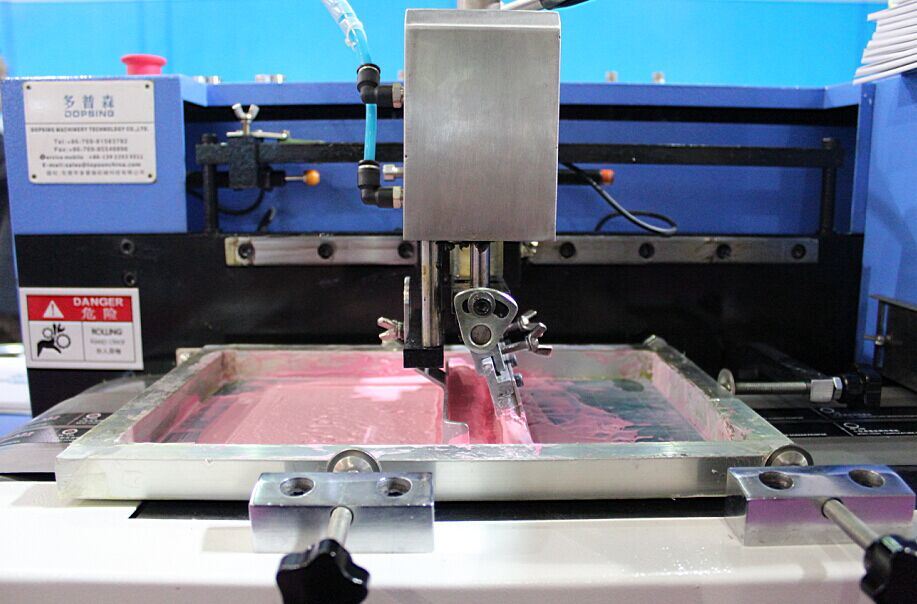

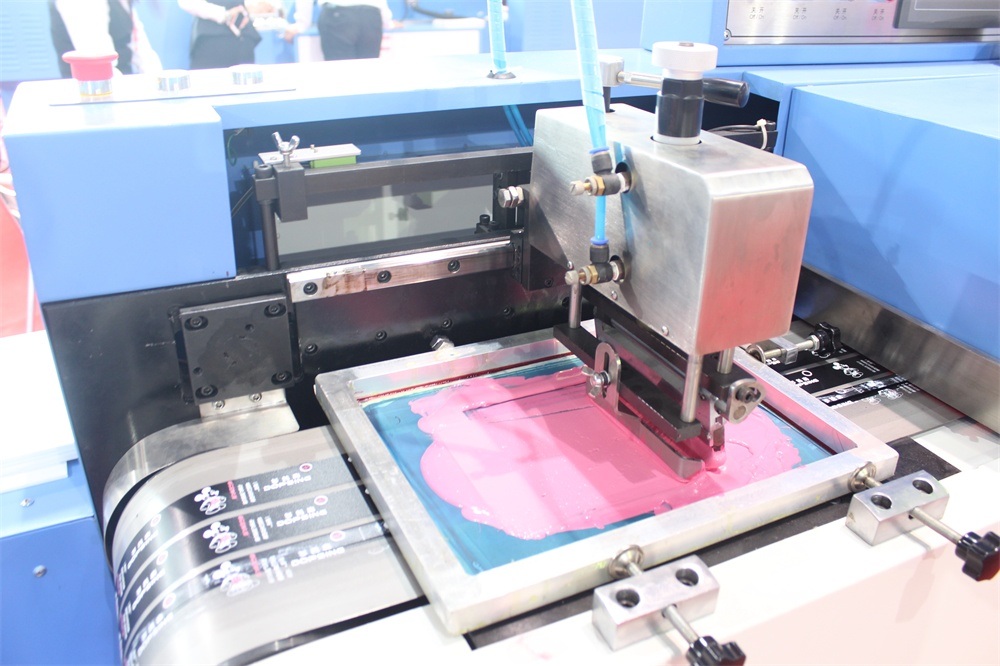

We supply Auto Roll to Roll Screen printing Printer, all are for fabric label and ribbon screen printing. It can print priciesly and two sides printing at one time. It’s the leader of the narrow fabric screen printing equipments. We have agents in many countries and branches in China.

Model No. TS-200

Usage, print any kinds of roll material, such as label, ribbon, cotton, elestic, shoelace, heavy tape, lanyard and so on

| Total Colors | Model | Single/Both Sides | Printing Lines | Max Printing Area | Dimension |

| 2 C | 1+1 | Both | 3Lines/3.5cm | 180X300mm | 2200X850X1600mm |

| 2 C | 2+0 | Single | 3Lines/3.5cm | 180X300mm | 3155X850X1600mm |

| 3 C | 2+1 | Both | 3Lines/3.5cm | 180X300mm | 2700X850X1600mm |

| 3 C | 3+0 | Single | 3Lines/3.5cm | 180X300mm | 3155X850X1600mm |

| 4 C | 3+1 | Both | 3Lines/3.5cm | 180X300mm | 3850X850X1600mm |

| 4 C | 4+0 | Single | 3Lines/3.5cm | 180X300mm | 4760X850X1600mm |

Advantage:

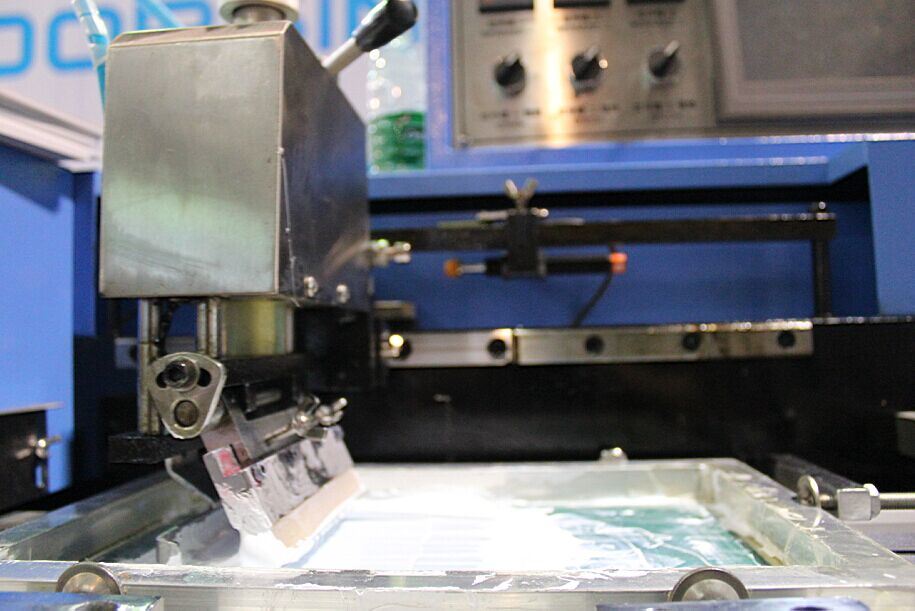

1. Using Stainless steel convey belt instead of traditional convey to make register color very precisely.

2. Standard colour: 2+1 (front side 2 -colours, back side 1 colour printing), this model we can customise as the requirement of our client.

3. Small in size, and not occupy your much room, dimention only 2.95M * 0.65M * 1.65M. Easy to install at any place.

4. Full automatic, it is controlled by a servo-system. Two infrared ovens.

5. High efficiency, save your time and your labour cost. Max Speed can up to 28 Times/Min.

6. Good thermostability with stainless steel belt convey, it can print any kinds of high temperature ink, such as plastisol, silicon, etc.

7. Multi tapes printed at one time.

8. Rational Price depend on how many colours do you want to print.

9. Long service life, if maintainance proper, its service life can up to more than 8 years.

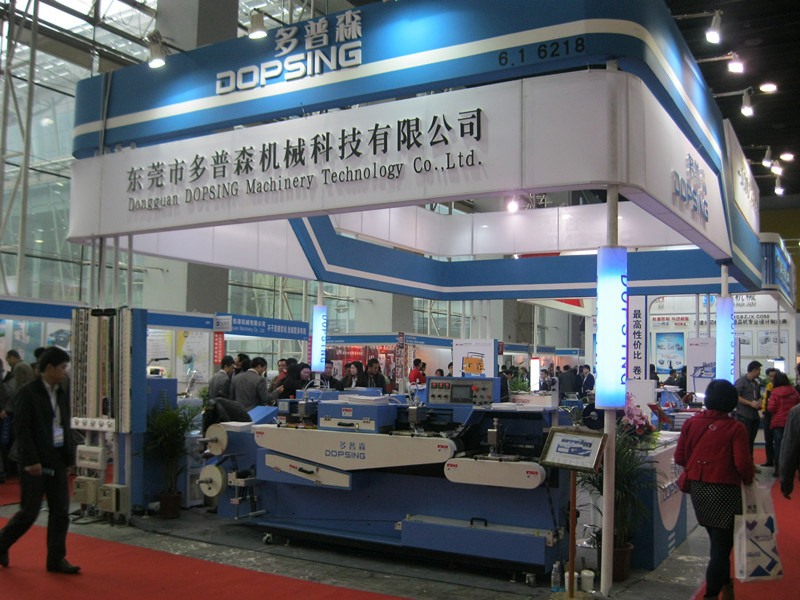

DOPSING Machinery Technology Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&label printing machine and mini High-Temperature Ribbon Screen Printer,label slitting machine,all are for fabric label and satin ribbon,lanyard,cotton tape etc.As the leader of the narrow fabric screen printing equipments,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co.,Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing. it has gained over than 10 patents from generation 1 to generation 3 of computerized screen printing machine.

Product detail pictures:

Related Product Guide:

Rob Sheffield’s 98 Best Songs of 1998 | Polyester Satin Ribbons Sample Continuous Dyeing Machine

Etimark installs new Screen Truepress Jet L350UV+LM | Luggage Belt Continuous Dyeing And Finishing Machine

Factory Price Nylon Bra Tapes Starching And Finishing Machine - Double Sides Cotton Tapes Automatic Screen Printing Machine – Kin Wah, The product will supply to all over the world, such as: , , ,

-

Low price for Automatic Silk Screen Balloon Pri...

-

Factory wholesale Automatic Label Silkscreen Pr...

-

China Gold Supplier for Cloth Labels Continuous...

-

Reasonable price for Fabric Screen Printing Mac...

-

2017 China New Design 5 Colors Silk Screen Prin...

-

Factory Price For Narrow Fabric Continuous Dyei...